Services

Supporting Your OCTG Needs

Our team can support your team’s drilling and completion engineers with the necessary expertise to properly select and deploy OCTG materials and connections. We offer services throughout the entire well life, from initial planning to running in the well and beyond. We have experience in critical wells including:

- Corrosive wells

- Extreme sour service

- High Pressure, High Temperature (HPHT), Deepwater, ERD

- Water Disposal and EOR Technologies

- Carbon Capture, Utilization, and Storage wells (CCS / CCUS)

- Geothermal

Field Engineering

More than just make-up and running supervision, our team is carefully selected and vetted to ensure they’re up to the task of optimizing your operations. We run a small, specialized team focused on high value and critical projects, capable to interact and share best practices with all involved.

- Critical wells – offshore, corrosive, and / or sour wells.

- CRA Make-up and running best practices (onshore, offshore, including subassemblies)

- Pipe Yard supervision, including yard audits and development

- Optimization of rig running operations – implement best practices, reduce mistakes, efficiently recover, and save time (NPT).

- Extensive experience in running of corrosion resistant alloys (CRA)

- Tubing / CRA Reclamation – CRA’s such as Nickel Alloys can often be recovered and re-used in wells, saving significant costs and reducing carbon impact of the project.

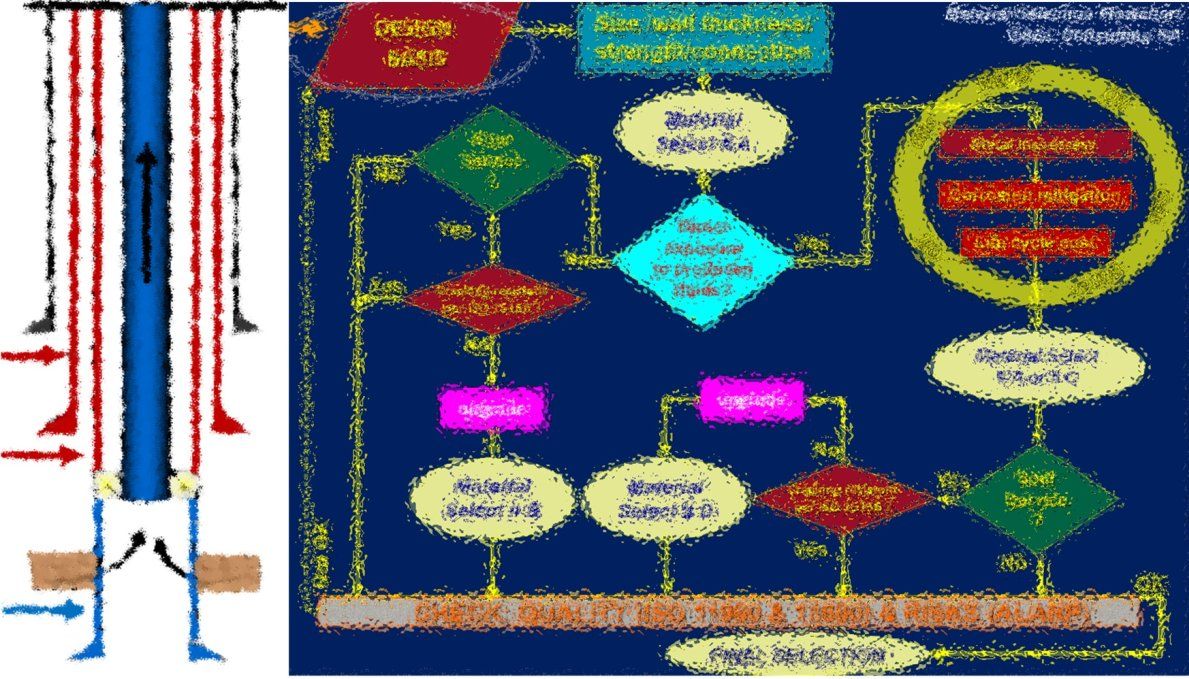

Casing/Tubing Selection and Design

- Initial screening of mechanical design through final design, including detailed Material Selection based on client’s basis of design and latest industry standards.

- Connection selection, including premium connections, we can assist in making the right choice and evaluating qualification tests

- Connection fatigue analysis

- Life Cycle Costing including carbon impacts (cost optimization)

- Coordination of qualifications, such as corrosion testing, connection testing, and production process / supplier qualifications

Specification and Quality Control

Specification of OCTG for when project criticality requires quality control above Industry Standards

Failure Analysis, including investigation on site through our Field Services and root cause failure analysis (RCFA)

Failure Analysis, including investigation on site through our Field Services and root cause failure analysis (RCFA)

Other Services

The above is just an overview – if the challenge is related to OCTG, we can help.

Our team has over 100 years of combined experience in OCTG. Contact us to inquire, and we look forward to finding a solution together.